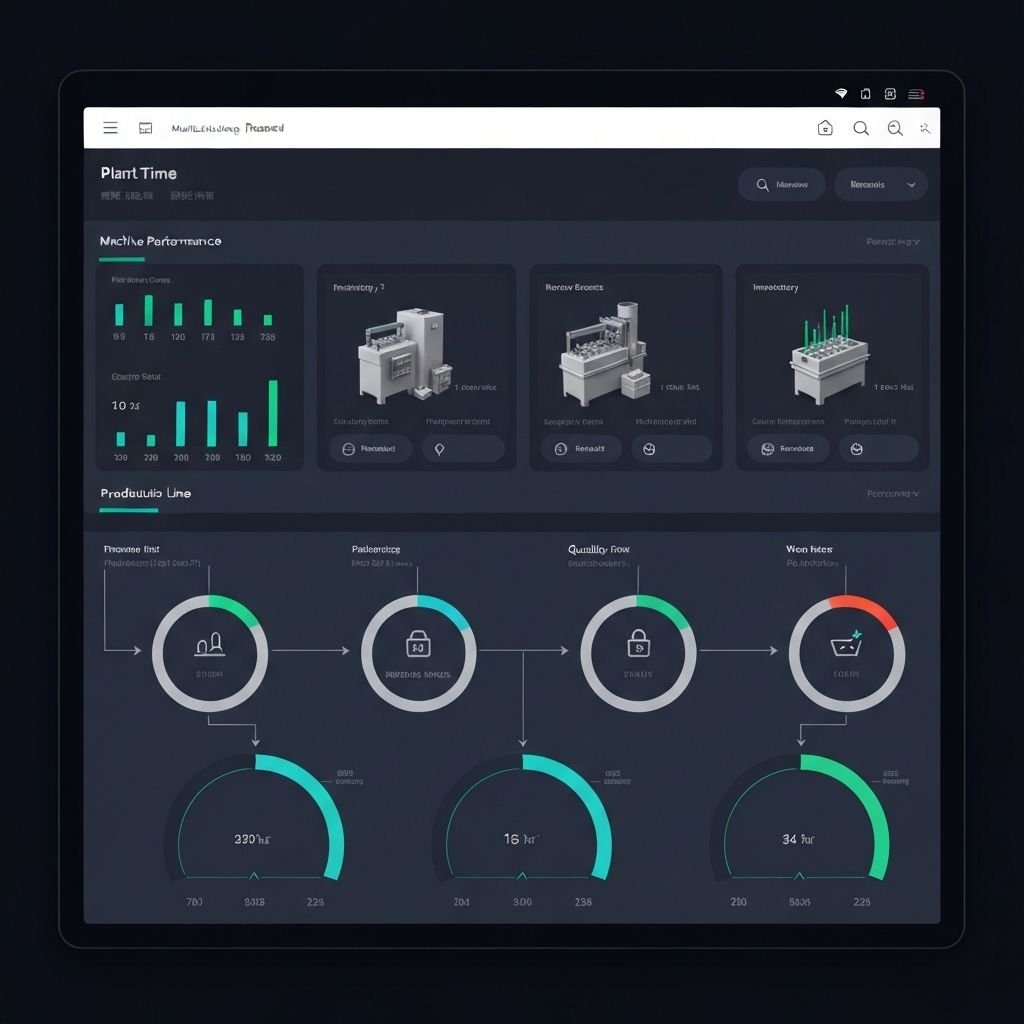

Manufacturing ERP

A configurable ERP for discrete, batch, or hybrid manufacturing—covering planning, production, quality, inventory, maintenance, and costing.

What the ERP does

Quotes → Orders → Invoices, Statements and Ageing.

Adjustments (Quantity/Cost), Stock Count, Movements and Valuation.

Purchase Orders and Supplier Invoices.

Receipts/Payments and Bank Reconciliations.

Operational Budgets and tracking.

Cost of Goods Sold (COGS), Accounts Receivable (AR)/Accounts Payable (AP), Value Added Tax (VAT) in the General Ledger (GL).

Capabilities

Everything you need from planning to shipment.

Plan materials and capacity with realistic constraints and priorities.

Track work orders through operations, labor, and scrap with real‑time WIP.

Inline checks with holds, CAPA, and COA generation.

Multi‑warehouse, lots/serials, and directed movements with traceability.

Roll‑up standard costs and capture actuals for variances and profitability.

Business Impact

Outcomes manufacturers see with Kidaftari.

Key reports you’ll use

- Profit and Loss (P&L)

- Inventory Movements & Valuation

- Sales and Purchases summaries

Ready to modernize production?

Connect planning, shop floor, and finance in a single ERP.